Pre-sintered ZYTTRIA Z401 WHITE TRASLUCENT, ZYTTRIA Z402 EXTRA-TRASLUCENT, ZYTTRIA Z402 EXTRA-TRASLUCENT PLUS and ZYTTRIA Z COLOR components are processed using the following procedure:

- Insert the component on the milling machine support

- Program milling considering the final dimensions of the structure

- Process the component with a tungsten carbide or diamond-point milling machine according to the manufacturer’s instructions of the system used

- Keep the product and tool clean during milling with jets of air or water

- Dry the structure with infrared lamps or drying ovens

- Before sintering, check the ceramic structure is undamaged

- Sinter the ceramic structure with a suitable kiln

- Remove the sintered structure from the kiln only after it has returned to room temperature

- Quality check with Concept MICROCHECK system that the sintered structures are free from microcracks

- Test the ceramic structure on the reference model, check its precision and, if necessary, make the appropriate grinding using water-cooled diamond-point turbines

- If necessary, sandblast the sintered structure with 60/100 micron aluminium dioxide at a pressure of 1-2 bar

- Clean the sintered structure with water. Do not use steam-jet equipments or autoclaves

There are natural radioactive impurities in Zirconium which may be eliminated using modern purification processes.

Once the impurities have been removed, Zirconia is considered to be a safe material. It is obviously important for the purification process which eliminates the radioactive impurities present to take place according to ISO standards.

CO.N.CE.P.T. uses high-quality Japanese powders, processed using the world’s leading-edge technologies, and, in any case, conducts the strictest controls when the raw materials arrive, including on radioactivity values.

Many scientific studies and publications confirm that levels of radioactivity of Zirconia (ZrO2) are very low and use of this material in the medical field may therefore be considered safe and biocompatible.

The maximum value of Becquerel (Bq) within which a material is considered safe for human health, set by ISO standards, is 0.2 Bq/g or 200 Bq/kg.

Zyttria products manufactured by CO.N.CE.P.T. have radioactivity values of <0,0011 Bq/g (Technology and Nuclear Institute - Unit of Radiological Protection and Safety - Sacavém), i.e. much lower than the maximum permitted value.

The individual phases are managed by operators in auto-control and, in any case, always with the supervision of the quality department staff.

Final control activities are performed on all products and involve:

- a visual control using lenses with magnifications;

- dimensional control;

- hardness control;

- control on fired density and therefore shrinkage.

The batches produced are duly grouped together on the basis of the amount of shrinkage and, for each group, the shipment lot is assigned and registered in order to guarantee prompt traceability of the material if necessary.

The whole Concept ceramic process is subject to severe monitoring

Pre-sintering is a delicate process.

It determines the processing characteristics of the product (e.g. hardness).

Even minimal thermal excursion may jeopardise uniform shrinkage of products.

CO.N.CE.P.T. guarantees precise control of the furnaces with sophisticated probe systems to guarantee a uniform internal temperature.

DIFFERENCES

Resistance to wear and mechanical resistance depend on the type of pressing used.

Isostatic pressing determines technical vaues 15% superior to those achieved with mono bi-axial pressing.

In order to obtain a blank of zirconia of highly-resistant and homogenous contraction of the product in all directions during the sintering phase, pressing must give the product homogenous density and porosity. Choice between axial or isostatic pressing therefore depends on the physical characteristics and geometries of each semi-processed product.

In contrast with axial pressing, isostatic pressing allows the pressure to be applied uniformly in all directions. The result is a “green product” (the name given to the pressed and not sintered product) characterised by a higher and more uniform density, which gives the sintered product excellent properties to the fired product, with mechanical and resistance values up to 15% higher than those of an axially pressed product.In fact, the lower internal porosity gives higher resistance to acids and therefore to the chemical agents present in the mouth, and also greater stability which delays deterioration and therefore aging during use.

Less inner porosity gives a higher resistance to acids and to chemical agents in the oral cavity, as well as a higher cohesion which delays wear and aging in operation.

Isostatic pressing technology is therefore undoubtedly preferable, due to its quality and technical characteristics, when complex work such as extended bridges and crowns with average/complex geometries are involved.

Many factors influence the final result of the prostheses made in Zirconia.

Zirconia blocks on the market, even though they are chemically similar to each other, once processed may have very different mechanical and optical characteristics.

In order to achieve a constant quality level, the manufacturing process of these materials requires a high level of specialisation, starting from preparation and control of the granulates. CO.N.CE.P.T. uses the best Japanese powders for production of semi-finished products in Zirconia.

Each lot of raw materials first goes through strict incoming controls, including:

- chemical composition

- radioactivity test

- granulometric distribution

- shrinkage control

- density control

Production process

Zirconia is obtained using chemical processes or through Zirconium Silicate and Baddeleyite electrofusion.

The quality of the granulate considerably influences porosity and possible defects in the sintered product:

- the size of the grains has an effect on performance of the material (nanometric dimensions of the crystals guarantee high mechanical resistance and high resistance to chemical agents)

- distribution of the grains, on the other hand, may influence hydrothermal stability of the sintered material.

- distribution of the additives influences the porosity and therefore translucency of the material. Medical applications need high-quality Zirconia purified with a controlled production process. The method used is hydrolysis of Zirconium sand, following purification with chlorhydric acid and subsequent calcination.

CO.N.CE.P.T. uses Japanese powders produced with this method.

Use of Zirconia (ZrO2) in medicine dates to 1969, when this material was adopted for the manufacture of hip prosthetics. As an alternative to titanium, steel or alumina, the new material guaranteed better resistance to breakage and corrosion, as well as a high degree of biocompatibility, confirmed by the fact that no negative response has been recorded, in around forty years of application, in 300 thousand patients with Zirconia prosthetics.

Use of ceramic materials to manufacture dental prosthetics dates to the 18th century. However, although these materials generally had excellent aesthetic properties, they were not widely used in dentistry due to low toughness which did not guarantee resistance to fractures. Porcelain was therefore used in a metal composite. Doubts over use of metal in the mouth, which has a low level of biocompatibility, shifted attention to other metal-free materials.

Over recent years, Zirconia has proved to be an excellent material for use in high-quality dental restorations, since its high mechanical/shock-resistant characteristics, fracture toughness and elastic module (Young) are associated with a high level of biological compatibility with gum and bone tissues.

Over recent years, Zirconia has proved to be an excellent material for use in high-quality dental restorations, since its high mechanical/shock-resistant characteristics, fracture toughness and elastic module (Young) are associated with a high level of biological compatibility with gum and bone tissues.

The technology which allowed stabilisation of the tetragonal phase, thereby preventing the typical transformation of Zirconia at room temperature (monoclinic crystalline structure) and keeping the tetragonal structure even after cooling at room temperature, was fundamental.

Partial stabilisation of Zirconia is obtained with the addition of ceramic oxides like Yttrium Oxide, Magnesium Oxide, Calcium Oxide or Cerium Oxide.

Yttria-stabilized Zirconia (ZrO2Y2O3) is the one mainly used for dental applications.

Partially Stabilized Zirconia

The minimum characteristics for clinical uses of Zirconia are indicated by standard EN-ISO 13356:

| Chemical composition | Standard ISO 13356:2008 |

| ZrO2 + HfO2 + Y2O3 Y2O3 | >99% |

| Y203 | from 4.5 % to 5.4 % |

| Hf203 | < 5 % |

| Al2O3 | < 0,5% |

| Other oxides | < 0,5 % |

Many qualities make Yttria-stabilized Zirconia (ZrO2Y2O3) particularly suitable for modern dentistry:

- excellent biocompatibility

- low specific weight

- high aesthetic quality, particularly in terms of translucidity

- elasticity similar to steel

- flexural strength (higher than 1,000 MPa) more than two times higher than steel

- compression resistance four times higher than steel

- breakage resistance which allows thicknesses lower than 1 mm to be used (maximum limit in use of precious alloys such as gold-platinum alloys), allowing extended, light and robust bridges to be manufactured

- high resistance to acids and therefore greater resistance to contact with food

- transparency to X-rays and non-magnetic (extremely useful in the case of X-rays, CAT scans, etc.).

In biomedical field, for the prosthetic restorations, the material considered more performant for its characteristics is zirconium oxide (ZrO2) - commonly called ZIRCONIA - which is an metal-free ceramic oxide, not to be confused with the zirconium (Zr) that is a metal instead.

The zirconium oxide ZrO2 is obtained from the zirconium silicate mineral, found in deposits located in Australia, Russia, USA, Brazil, India and South Africa, or Baddeleyte, whose deposits are found mainly in South Africa and Sri Lanka

Raw material

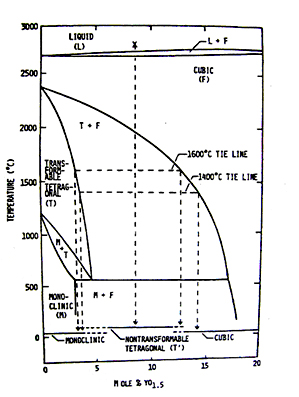

Zirconium DiOxide (ZrO2), known as Zirconia (non to be confused with Zircon metal, is a polymorphous substance, meaning its crystalline structure may alter without altering the original chemical composition. At atmospheric pressure, Zirconia has three polymorphous phases:

- Monoclinic

- Tetragonal

- Cubic

-

At room temperature, up to 1170 ° C, it has a monoclinic crystalline structure.

-

From 1170° C to 2370° C, the crystalline structure transforms from a monoclinic to a tetragonal structure, with a volumetric contraction of approximately 5%.

-

Above 2370° C, it transforms into a cubic crystalline structure.

The phase transformations are reversible and influence the performance of the material, which is modest in the monoclinic and cubic phases, but become more interesting in the tetragonal phase.

Tetragonal to monoclinic transformation is martensitic: during cooling, the tetragonal structure transforms into a monoclinic structure, with an expansion in volume varying between 3% and 5% and exceeding the elastic limit of Baddeleyite, causing microcracking in the structure.

This mechanism, which could, at first glance, appear to cause a negative effect on performance of the material, is actually used to increase resistance and toughness.

In fact, although cracks form in ceramic under loads, the surrounding Zirconia crystals transform into the monoclinic structure. The pressure tensions which form close to the crack, due to expansion of the material, stop it from spreading. These “crack-blocking functions” give high values of resistance to breakage and toughness.

In fact, although cracks form in ceramic under loads, the surrounding Zirconia crystals transform into the monoclinic structure. The pressure tensions which form close to the crack, due to expansion of the material, stop it from spreading. These “crack-blocking functions” give high values of resistance to breakage and toughness.

It is possible to maintain the tetragonal phase at room temperature through partial stabilisation of the Zirconium with the addition of 3-6% of Magnesium Oxide (MgO), Yttrium Oxide (Y2O3), Calcium Oxide (CaO) and Cerium Oxide (Ce2O3).

CO.N.CE.P.T. (Compagnia nuove ceramiche per la tecnica) unites Italian know-how in the field of high level technical ceramics and German technology.

CONCEPT is run by Dott. Ing. Aldo Caso, who has a lot of experience in the field of technical ceramics and more than 30 years of experience as Production Manager in leading companies for innovative/aerospace materials.

The production is made in Busseto (Parma), known for being the city where the musician and composer Giuseppe Verdi was born; it ensures technical reliability and the flexibility required to meet constantly evolving market needs.

Made in Italy is expressed in the guidelines of CONCEPT: manufacturing quality, traceability and quality of raw materials, control at each production stage.

In the Dental Laboratory

Technology and innovation are not enough on their own to achieve high quality because of increasing complexity of the products; it requires a continuous update of the knowledge of the production processes.

Made in Italy products by CONCEPT own not only quality and control on each step of the production process, but there is also a new idea of work style. CONCEPT provides competences and its own experience as a producer in order to find a correct answer to technical problems of dental laboratories about materials and their behaviour during the processing.

Italian product, German technology

Production is made only with isostatic technology, in order to assure the most appropriate technical performances for medical use.

We are developing products made of Zirconium Oxide, used in the production of ceramic dental prostheses with the shape of small blocks, cylinders and discs compatible with the most common CAD-CAM milling machines and manual pantographs.

There are seven product lines:

-

- Z404 SUPER-TRASLUCENT

- Z COLOR SUPER-TRASLUCENT

- Z MULTICOLOR SUPER-TRASLUCENT

Checked Quality

Our products are registered with the trade mark ZYTTRIA® and are classified in Class IIA (93/42/EEC and 2007/47/EC).

The quality control is very strict and is carried out at each stage of the production process, starting from selection of raw materials supplied by certified Japanese companies. Traceability of the components used is guaranteed throughout the whole production chain.

The production system complies with the following standards:

- UNI CEI EN ISO 13485:2016

- UNI EN ISO 9001-2015

- Dir. 93/42/CE adeguata alla dir. 2007/47/CE

- CE 0476.